CONTAINER TOTE AVIATION GENERAL DUTY

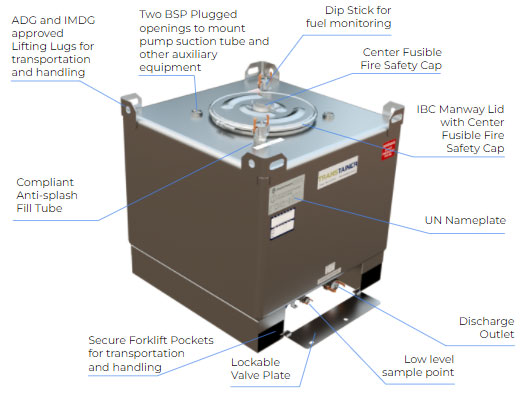

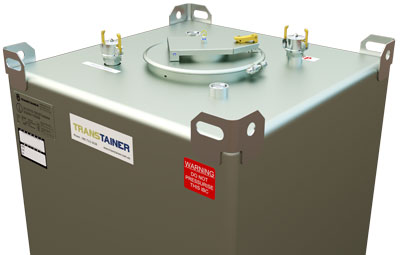

Transtainer Container Tote Aviation General Duty “CTAVGD” IBC Series are United Nations IMDG approved Stainless Steel Intermediate Bulk Containers (IBC’s) specifically designed for the transportation, storage and decanting of “Aviation fuel” Avgas and Jet A1. The tanks are commonly referred to as IBCs and Totes.

Transtainer IBC’s include mandatory safety features accredited by the United Nations IMDG certification system such as: compliant anti-splash fill tube, IMDG approved crane lifting lugs, low level sample valve at the lowest point in the tank, center fusible cap to comply with fire safety requirements, dipstick for fuel monitoring and optional pressure vacuum vent and pump suction tube.

Transtainer Aviation IBC’s feature four top mounted BSP sockets for ease of customisation for specific refuelling requirements. All sockets can be modified to NPT thread or flanges.

| Features and Benefits | Usage | Capacities | Applications |

|---|---|---|---|

| UN31A/Y Approved Field Proven Design Reduced Contamination Minimal Residual 20 units per 20 ft FCL (1000L) for global shipping |

Delivery Storage Transportation Decanting |

500 litres 1,000 litres 1,250 litres 1,500 litres 1,750 litres 2,000 litres |

Flammable Liquids Corrosive Liquids Hazardous Liquids Combustible Liquids |

PRODUCT EQUIPMENT AND MATERIAL DATA

The Aviation IBC Totes are available as:

- The IBC with standard operation and safety equipment

- The Standard IBC plus optional equipment/parts

| Standard Equipment | – Discharge: 50mm ball valve c/w camlock – Fill: 50mm compliant anti-splash fill tube c/w camlocks – 20mm Low level sample collection point ball valve c/w camlocks – Dipstick for storage monitoring- IMDG compliant lifting lugs – Centre cap featuring fusible safety link – Temperature relief 138°C |

| Auxiliary / Optional Equipment | – Dry break couplings – Pumping solution including suction tube – Pressure / vacuum vent +35kPa / -3.5kPa |

| Materials and Options | – Shell: 2.5 to 3mm stainless steel 304 plate (volume dependent) – 316L stainless steel optional – Skid assembly: 3mm stainless steel 304 plate and sections – Camlocks in Stainless Steel 316 – Valves in Stainless steel 316 – Manway gasket: in Nitrile, PTFE, EPDM or Viton |

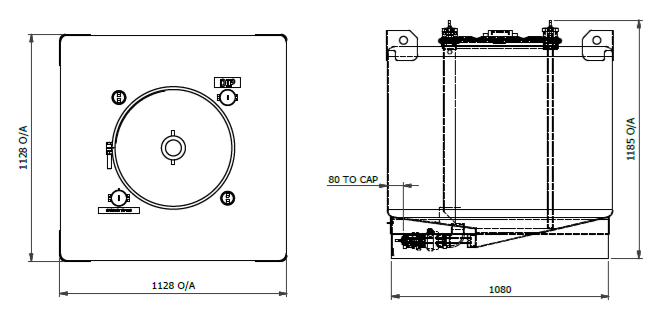

PRODUCT CODES AND DIMENSIONS

| Product Code | Capacity (L) | Length (mm) | Width (mm) | Height (mm) | Weight (kg) |

|---|---|---|---|---|---|

| CTAVGD500 | 500 | 1128 | 1128 | 784 | 148 |

| CTAVGD1000 | 1,000 | 1128 | 1128 | 1184 | 160 |

| CTAVGD1250 | 1,250 | 1128 | 1128 | 1384 | 202 |

| CTAVGD1500 | 1,500 | 1128 | 1128 | 1584 | 258 |

| CTAVGD1750 | 1,750 | 1128 | 1128 | 1784 | 280 |

| CTAVGD2000 | 2,000 | 1128 | 1128 | 1984 | 290 |

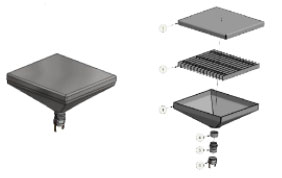

OUTSIDE FEATURES

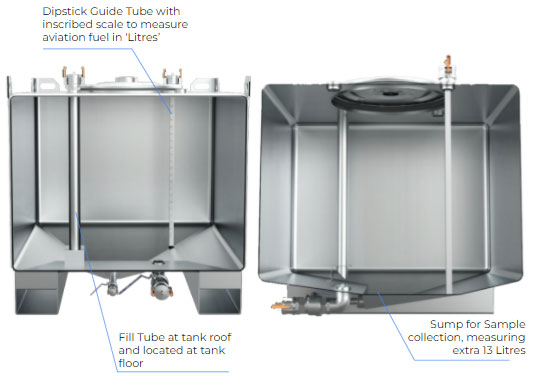

INSIDE FEATURES

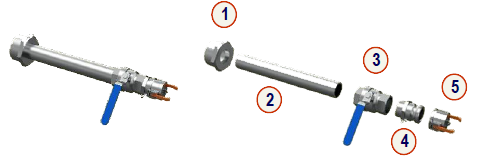

STANDARD PARTS

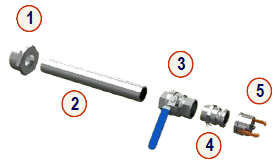

Discharge Outlet

Controlled and secure discharge outlet complete with ball valve and cam lock assembly

Specifications

- Elbow 90° 50mm Male-Female SS316

- Hex Nipple 50mm BSP SS316

- Ball Valve 50mm Female-Female SS316

- Camlock 50mm Male-Male SS316

- Camlock Dust Cap 50mm

Fill Inlet

Secure and Compliant anti-splash fill tube with anti-siphon hole

Specifications

- Pipe 50mm threaded-end BSP SS

- Anti-siphon hole

- Camlock 50mm Male-Female SS316

- Camlock Dust Cap 50mm SS316

Sample Collection Outlet

Low level sample collection outlet

Specifications

- Bush 50mmx20mm SS316

- Pipe 20mm threaded-end BSP SS304

- Ball Valve 20mm Female-Female SS316 (w/ Locking Device)

- Camlock 20mm Male-Male SS316

- Camlock Dust Cap 20mm SS316

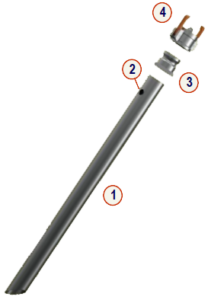

Dip Stick

For fuel monitoring

Specifications

- CT Dip Stick Bottom Plate SS304? welded to tank

- CT Dip Stick Guide Tube with inscribed scale in Litres SS304?

- CT Dip Stick SS304

- Camlock 50mm Male-Male SS316

- Camlock Dust Cap 50mm SS316

STANDARD PARTS

| Discharge Outlet | Exploded Parts | Specifications |

|---|---|---|

Controlled and secure discharge outlet complete with ball valve and cam lock assembly |

|

|

OPTIONAL PARTS

| Pressure / Vacuum Vent | Specifications |

|---|---|

Designed to protect the tank from any over-pressure or any vacuum in excess. |

|

| Dry Break Coupling | Specifications |

|---|---|

| Ensures quick and safe connection of hose assemblies and loading arms to mobile and stationary tanks under pressure and with minimised liquid loss. Both coupling parts are equipped with a flat poppet valve to control the flow.  |

|

| Desiccant Filter | Specifications |

|---|---|

Combined Air Breather and Water Removal Filter Air flowing into the tank through the desiccant breather, initially passes through the drying material and then through an air filter element to filter out the contained dirt particles. The condition of the drying material changes as the absorbed moisture increases and the colour changes gradually from red to orange. |

|

| Cleaning Spray Ball | Specifications |

|---|---|

The main purpose of rotary spray ball is to wash medium and small-shaped inner tank containers. Effective cleaning, low energy consumption, at any angle, comprehensive universal washing tank, alternative to traditional static spray because it uses low volumes of cleaning fluid at low pressure. Remove accumulated particles in the tank wall material, thus ensuring a sterile tank |

|

| Funnel | Specifications |

|---|---|

IBC Funnels are great for easy and spill-free filling of intermediate bulk containers. These IBC funnels are resistant towards chemicals and are ideal for industrial use. |

|

| Sparge | Specifications |

|---|---|

|

|

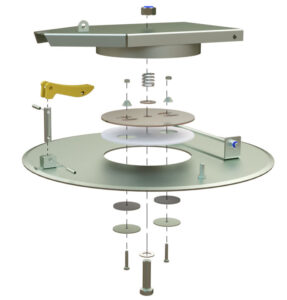

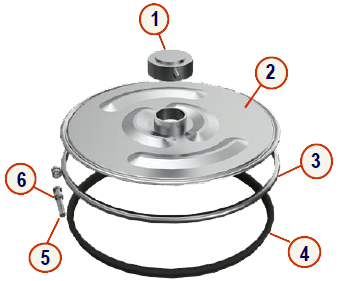

| PRESSURE MANWAY | Specifications |

|---|---|

|

The pressure manway is sealed to the top of the IBC with a nitrile seal, then the clamp band is tightened until air tight. The pressure pallet performs in the same way as a vent. On the vent, a spring mechanism will open at – 3.5 kpa to allow atmospheric air to enter the tank. When the tank reaches a pressure level of 21 Kpa, the spring will open again to relieve air from the tank. In the event of fire, the pin mechanism on the latch will fail at 138 degrees centigrade. After the failure of the pin, the hatch assembly will open and the tank will vent to the atmosphere through the open hatch. Pressure Setting : 21 kPa Vacuum setting : -3.5 kPa Temperature Setting : 138oC |

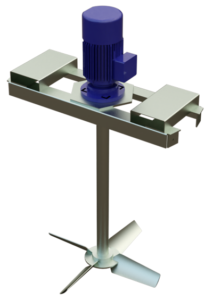

| IBC Mixer / Agitator | Specifications |

|---|---|

|

High efficiency agitators and tank mixers options available to meet the jet fuel mixing requirements and to suit the CT Aviation IBC structure. The top-entry agitator mixers incorporate advanced designs in mixing technology achieving ultimate blending & mixing conditions in open or closed top vessels.

|

| Pallet Skid Unit | Specifications | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Transtainer CT IBC Pallet Skids are designed to suit their Container Tote series of Intermediate Bulk Containers for transportation and handling purposes.

|

||||||||||

| Pallet Skid Unit | ||||

|---|---|---|---|---|

|

PIUSI PUMP ASSEMBLY

| PIUSI Fuel Pumps | Specifications |

|---|---|

|

PIUSI fuel pumps are transfer pumps suitable for flammable fuels such as gasoline, kerosene, and diesel. These are easy to use, versatile, and compact and adapts to your requirements.

|

|

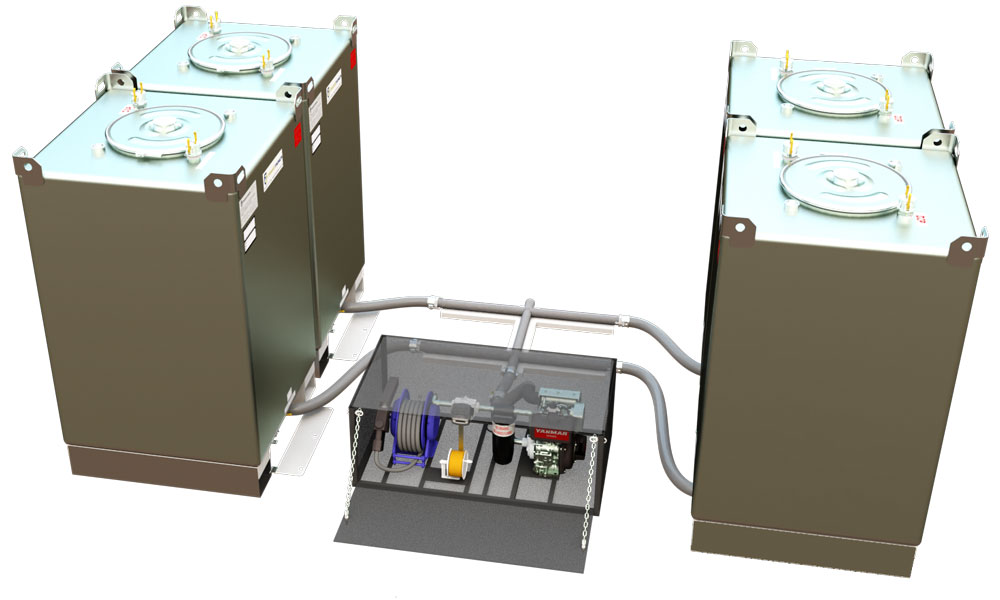

YANMAR PUMP ASSEMBLY

| Yanmar Fuel Pumps | Specifications |

|---|---|

|

The Yanmar diesel-driven pumps are strong working machines to work through heavy duty environments like mining, drilling, agricultural, marine, suburban industries, and oil & gas. The strong engine exceeds the power and environmental expectations. The pump uses Yanmar’s own efficient combustion system with low fuel consumption. Great for strong fluid transfer applications. |

Yanmar CI15 L48 Powered by Yanmar Diesel Engine L48. Electric start optional Engine Horsepower: 4.8HP Direct injection engine with easy installation Low noise and low vibration Material: Anodised Cast Iron casing, Bronze impeller, Silicon Carbide Mechanical seal, Viton Elastomer Inlet/Outlet diameter: 40mm Pumps up to 350 Litres/min Strainer Included Speed: 3400 rpm Weight: 56 kg |

PUMPING ACCESSORIES

| Suction Tube | Specifications |

|---|---|

|

|

| Hose Reel | Specifications |

|---|---|

Heavy duty jet fueling hose reel with spring-rewind and twin pedestal supports. Heavy duty jet fueling hose reel with spring-rewind and twin pedestal supports. |

|

| Cut-off Fuel Dispensing Nozzle | Specifications |

|---|---|

The dispensing nozzle is ATEX certified, fitted with a device that automatically shuts off flow when the tank is full, preventing an overfill scenario. It is designed for a quick and clean refuelling. The dispensing nozzle is ATEX certified, fitted with a device that automatically shuts off flow when the tank is full, preventing an overfill scenario. It is designed for a quick and clean refuelling. |

|

| Fuel Dispensing Meter | Specifications |

|---|---|

The ATEX certified flow meter has been engineered for an accurate measuring of the quantity of fluid dispensed that meets the ATEX/IECEx requirements related to the use in potentially explosive atmospheres. The ATEX certified flow meter has been engineered for an accurate measuring of the quantity of fluid dispensed that meets the ATEX/IECEx requirements related to the use in potentially explosive atmospheres. Reliable and easy to install, it can be calibrated on site and simply fitted with both rigid or flexible pipes or can be put directly on pumps and tanks. . |

|

| Fuel Tank Filter | Specifications |

|---|---|

Fuel Tank Filter removes both water and particles out of diesel to a micron rating. This diesel storage tank filter can be installed before or after the pump, and has a spin on cartridge, which makes it easy to be replaced when it starts to get full. Fuel Tank Filter removes both water and particles out of diesel to a micron rating. This diesel storage tank filter can be installed before or after the pump, and has a spin on cartridge, which makes it easy to be replaced when it starts to get full.. |

Cannister filter: 30-micron Inlet diameter: 25mm F BSP Flanged Outlet diameter: 25mm F BSP Flanged 25mm-12 F UNF Filter Thread Max. flow rate: 70 Litres/min Suitable for diesel and petrol Includes 1 x filter head and 2 x filter element |

Material: 316 stainless steel

Material: 316 stainless steel